Basement slab and first floor framing

Caution, lots of photos this week.

This week we finished installing the interior drainage plane for the foundation walls, insulating the floor under the basement slab and pouring the slab. We also framed out the first floor exterior walls. The weather held out till Saturday afternoon when a cold rain forced us to stop.

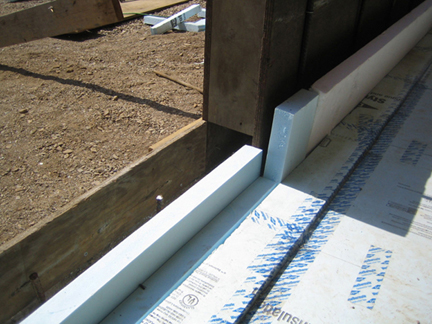

We used extruded polystyrene foam (XPS, the blue stuff) under the slab because of its greater compressive strength. We laid two layers of 2 inch foam, then a layer of 6 mil polyethylene as our radon gas barrier. We used acoustical sealant to attach the poly to the drainage plane on the wall to complete our radon gas barrier. Then we laid another 2 inches of XPS foam for a total for R30 under the slab. The top 2 inches of the foam lies on top of the footing. We placed another 2 inches of expanded polystyrene (EPS, the white stuff) on the walls sitting on top of the XPS foam. EPS is more environmentally friendly than XPS. This overlap isolates the concrete slab from the foundation and walls, keeping it dry and warm.

The concrete arrived Friday. They poured and leveled 4 inches of concrete on top of the foam. They also poured a small knee wall in the walkout area and the footings for the deck on the west side of the house.

Above, we raised the first floor exterior walls. You can now start to get a sense of the size of the space and the view out the framed openings. Of course it will feel a bit smaller when we frame up the interior walls, and smaller still when we put up the sheathing and finally the interior drywall. Now you can see the house when driving up the driveway.

Categories

- Air sealing 13

- Appliances & Fixtures 4

- Art 3

- Award 4

- Bathroom 8

- Batteries 1

- Decor 5

- Design 10

- Electrical 5

- Energy Calculations 13

- Energy Monitors 4

- Farm 1

- Finance 1

- Flooring 3

- Foundation 9

- Framing 8

- Heating 9

- House 7

- Insulation 8

- Kitchen 6

- Landscaping 3

- Lessons Learned 1

- Performance 60

- Plumbing 10

- Porch 5

- Radon 1

- Rainwater catchment 3

- Research / study 1

- Roof 7

- Septic / Waste water 2

- Sheetrock 6

- Siding 9

- Site Work 22

- Smart home 1

- Solar 64

- Solar Obsessed 10

- Stairs 2

- Surveying 3

- Ventilation 8

- Weather 1

- Windows & Doors 14

- plug-in 3

Archive

- Jan 2021 1

- Dec 2020 2

- May 2020 1

- Jan 2020 1

- May 2019 1

- Jan 2019 3

- Sep 2018 2

- Aug 2018 2

- Jan 2018 1

- Oct 2017 2

- Apr 2017 1

- Jan 2017 1

- Oct 2016 2

- Aug 2016 1

- Apr 2016 2

- Jan 2016 2

- Nov 2015 2

- Oct 2015 1

- Jul 2015 1

- May 2015 1

- Apr 2015 1

- Jan 2015 1

- Dec 2014 1

- Nov 2014 2

- Oct 2014 4

- Sep 2014 2

- Aug 2014 1

- Jul 2014 1

- Mar 2014 3

- Feb 2014 2

- Jan 2014 2

- Nov 2013 1

- Oct 2013 1

- Sep 2013 1

- Jul 2013 3

- Apr 2013 3

- Jan 2013 3

- Dec 2012 2

- Nov 2012 3

- Oct 2012 1

- Sep 2012 3

- Aug 2012 3

- Jul 2012 2

- Jun 2012 1

- May 2012 3

- Apr 2012 2

- Mar 2012 4

- Feb 2012 4

- Jan 2012 5

- Dec 2011 4

- Nov 2011 9

- Oct 2011 10

- Sep 2011 9

- Aug 2011 6

- Jul 2011 6

- Jun 2011 12

- May 2011 8

- Apr 2011 4

- Mar 2011 5

- Jan 2011 6

- Dec 2010 9

- Nov 2010 3

- Oct 2010 4

- Sep 2010 6

- Aug 2010 8

- Jul 2010 6

- Jun 2010 3

- May 2010 3

- Apr 2010 1

- Mar 2010 3

- Feb 2010 3

- Dec 2009 1

- Jun 2009 1

- May 2009 1

- Feb 2009 1

- Dec 2008 1

- Nov 2008 1

- Jun 2008 1